Quick Read

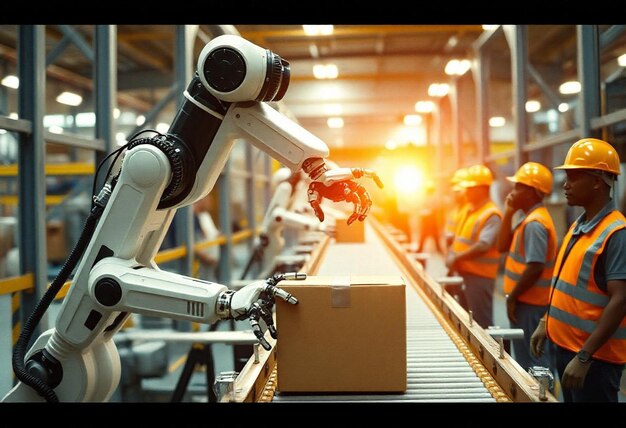

Amazon’s Robot Revolution: The Future of Warehouse Automation

Amazon, the world’s largest online retailer, is leading the charge in warehouse automation with its

robot revolution

. This

technological evolution

is aimed at streamlining operations, enhancing productivity, and improving overall efficiency in Amazon’s vast warehouse network. The company has already deployed thousands of

automated machines

, from robot arms to self-driving carts, in its fulfillment centers worldwide.

The

robotic workforce

is designed to take on monotonous and labor-intensive tasks, enabling human workers to focus on more complex functions. For instance, Amazon Robotic Fulfillment Units (RFUs) can move and stack shelves, while RoboDrive carts transport products around the warehouse, all without human intervention. Moreover, Amazon’s

newly introduced 10-foot robotic arms

can handle a variety of items, including bulky and oddly shaped ones.

However, the integration of robots into Amazon’s operations has not been without challenges. Implementing such advanced technology requires significant investment and ongoing maintenance, posing financial risks for the company. Additionally, there are concerns about the potential displacement of human workers as robots increasingly take over labor-intensive roles.

Despite these challenges, Amazon remains committed to its robot revolution. The company believes that automation will lead to a

more efficient and cost-effective

warehouse network, ultimately benefiting consumers with faster delivery times and lower prices. Moreover, Amazon is continuously exploring new ways to utilize robots alongside human workers, aiming for a

symbiotic relationship

that maximizes the strengths of both parties.

In conclusion, Amazon’s robot revolution is a significant step forward in the world of warehouse automation. By integrating advanced robotic technology into its operations, Amazon aims to enhance productivity, streamline processes, and improve overall efficiency in its vast network of fulfillment centers. However, the challenges associated with this technological shift must be carefully managed to ensure a successful transition for both Amazon and its workforce.

Revolutionizing E-commerce: Amazon’s Innovative Approach to Robotics and Automation

E-commerce, the buying and selling of goods or services over the Internet, has revolutionized the way we shop and conduct business in the digital age. With the link projected to reach $5.5 trillion by 2021, it is no surprise that companies are continuously seeking ways to optimize their operations and fulfill customer demands more efficiently. One of the most significant trends in e-commerce logistics is the increasing demand for warehouse automation. This article will explore Amazon’s innovative approach to robotics and automation in its warehouses, and how it is revolutionizing the industry.

Brief Overview of the E-commerce Industry and Amazon’s Dominance

The e-commerce industry has grown exponentially over the past two decades, with companies such as Amazon leading the charge. According to a recent report by Statista, link amounted to $3.5 trillion in 2019 and are projected to reach $7.4 trillion by 2025. Amazon, the world’s largest online retailer, accounts for approximately 38% of all e-commerce sales in the US.

Explanation of the Increasing Demand for Warehouse Automation

As e-commerce continues to grow, there is a greater need for companies to streamline their logistics processes. Traditional warehouses and distribution centers, with their reliance on manual labor, are increasingly becoming less efficient. In contrast, automated warehouse systems can process orders faster, reduce labor costs, and improve accuracy. Additionally, the global pandemic has accelerated the adoption of automation in e-commerce due to the need for contactless fulfillment and delivery.

Amazon’s Innovative Approach to Robotics and Automation

Amazon has been at the forefront of e-commerce innovation since its inception, and its approach to robotics and automation is no exception. The company’s link team is responsible for designing and developing advanced robotics systems to automate its fulfillment centers. One of the most notable examples of Amazon’s automation efforts is its Amazon Robotics initiative, which includes several robotics platforms such as:

- Amazon Picking Challenge: A robotic arm competition to improve product picking and sorting for warehouses.

- Amazon RoboMaker: An open-source robotics simulation platform to develop, test, and deploy intelligent robots.

- Amazon Scout: A delivery robot that can navigate sidewalks and deliver packages to customers in select neighborhoods.

Background: The Need for Automation in Amazon’s Warehouses

Amazon, the world’s leading online retailer, prides itself on providing efficient and fast delivery to its customers. The company’s business model is based on offering a vast selection of products, low prices, and convenient services like Amazon Prime, which promises free two-day shipping. However, meeting these delivery demands poses significant challenges in managing Amazon’s massive warehouse operations.

Scale:

Amazon operates more than 175 fulfillment centers worldwide, with each facility spanning over a million square feet. This vast scale requires an immense amount of manpower for managing inventory, order picking, packing, and shipping. Human labor, while essential, can only go so far in handling the sheer volume of orders.

Speed:

Fast delivery is a critical differentiator for Amazon. The company aims to process and dispatch orders within hours, if not minutes, of receiving them. Human labor, however, is subject to physical limitations and inconsistencies that can slow down the process.

Accuracy:

Ensuring accurate order fulfillment is another major challenge. With millions of items in stock, human pickers can easily make mistakes, causing delays and incorrect shipments. Improving accuracy while maintaining speed is a complex issue that automation could potentially help address.

Cost:

Maintaining low costs is essential to Amazon’s business model. Human labor represents a significant portion of the operational expenses, especially given the large scale and high turnover rates. Automation offers the potential for cost savings through increased efficiency and reduced errors.

The Limitations of Human Labor

Despite the crucial role that human labor plays in Amazon’s warehouses, it comes with inherent limitations. Human workers are susceptible to physical and mental fatigue, leading to decreased productivity and increased error rates. Additionally, the high turnover rate in warehouse jobs means constant training and supervision are required.

In Conclusion

Automation in Amazon’s warehouses is not just a luxury but a necessity to meet the company’s demands for speed, accuracy, and cost-effectiveness. By integrating automation technologies like robotics, drones, and autonomous vehicles, Amazon aims to streamline its warehouse operations while enhancing the overall customer experience.

I Amazon’s Early forays into Warehouse Automation

Amazon, the world’s leading online retailer, has always been at the forefront of technological innovation to enhance its operations and customer experience. In this regard, one of Amazon’s significant milestones in logistics and supply chain management came with the development and implementation of Amazon Robotic Technology (ART) in 2012.

Development and Implementation of Amazon Robotic Technology (ART) in 2012

In an effort to revolutionize its warehouse operations, Amazon acquired Kiva Systems, a robotics company, in 2012 for about $775 million. Renamed “Amazon Robotics,” this new division focused on automating tasks within Amazon’s fulfillment centers using robots. The first ART-powered warehouse, “Dallas,” opened in 2013.

Description of Kiva Systems Robots and Their Role in Automating Order Picking and Inventory Management

The Kiva System robots, a collection of autonomous mobile robots (AMRs), were designed to navigate warehouses and move shelves containing inventory to the appropriate picking stations, enabling workers to easily retrieve items for orders. These AMRs could be programmed to recognize various objects in their environment and navigate around obstacles. The integration of these robots significantly improved the speed and accuracy of order picking, as well as inventory management.

Analysis of Benefits: Increased Productivity, Improved Accuracy, and Labor Cost Savings

The implementation of ART led to several benefits for Amazon. Firstly, the increased productivity: instead of having employees walk long distances to pick up inventory items, robots moved shelves to them, reducing travel time and allowing associates to focus on tasks that required more attention.

Secondly, the improved accuracy: with robots handling inventory movement and storage, Amazon was able to minimize errors caused by manual labor. Additionally, the automation of inventory management reduced the time needed for cycle counts and stocktake, ensuring a more consistent inventory level and, ultimately, improving customer satisfaction.

Lastly, Amazon enjoyed significant labor cost savings: by automating repetitive tasks such as moving shelves, the company could reduce its workforce in certain areas without compromising efficiency. This shift towards more efficient labor allocation and automation became a cornerstone of Amazon’s operations, shaping the future of warehouse logistics and supply chain management.

Expansion and Advancement of Amazon’s Robotics Initiatives

Amazon’s foray into robotics began in a significant way with the acquisition of Kiva Systems in 2012 for a staggering $775 million. This Boston-based company, now known as Amazon Robotics, was pioneering the development of robotic systems for material handling and order fulfillment in warehouses. With this acquisition, Amazon gained access to Kiva’s innovative technology and the talented team behind it.

Launch of Amazon Robotics in 2014

Amazon officially launched its Amazon Robotics division in 2014, focusing on research and development to create advanced robotics technologies for various applications. The goal was to increase the speed, efficiency, and agility of Amazon’s warehouse operations while reducing costs and improving customer satisfaction.

Introduction of New Robot Types

Amazon’s robotics initiatives continued to advance with the introduction of new robots for different tasks. One such robot is the Proteus, which can move around in a warehouse environment and adapt to changing conditions, making it perfect for tasks such as inventory management and order picking. Another robot, the StowBot, was designed specifically for stowing items in Amazon’s warehouse shelves, further streamlining the order fulfillment process.

By combining the talent and technology from Kiva Systems with its vast resources and innovative culture, Amazon’s robotics initiatives have positioned the company at the forefront of automation and logistics technology.

The Impact of Amazon’s Robotics on the Warehouse Automation Industry

Amazon’s foray into robotics and automation in its warehouses has revolutionized the way we think about supply chain management and logistics. With the company’s commitment to

next-day delivery

and

continuous innovation

, it’s no surprise that Amazon has significantly influenced competitors in the warehouse automation industry. Let’s take a closer look at how this influence has manifested:

Competitor Adoption: Traditional warehouse automation companies have recognized the need to innovate and keep up with Amazon’s advanced capabilities. Some, like

Dematic

and

KNAPP

, have been quick to adopt robotics technology in their offerings. Others, like Bosch Rexroth and

Siemens Logistics

, are investing in research and development to stay competitive.

Setting New Industry Standards: Amazon’s warehouse robotics have set new standards for efficiency, agility, and adaptability. For instance, their use of

autonomous mobile robots (AMRs)

for order picking and fulfillment has resulted in significant time savings. Competitors are now following suit, with some even surpassing Amazon’s capabilities by integrating machine learning and AI into their systems.

Further Innovation and Collaboration

As the competition in warehouse automation heats up, there’s an opportunity for even more innovation and collaboration between companies and researchers in the field. Some potential areas of exploration include:

- Advanced robotics: Combining machine learning, computer vision, and 3D sensing to create robots that can navigate complex warehouse environments more effectively.

- Collaborative robots: Developing systems where humans and robots work together seamlessly to improve productivity, safety, and flexibility.

- Cloud robotics: Leveraging cloud computing to enable real-time processing of data from robots in the field, improving decision-making and reducing latency.

- Robotics as a Service: Providing robotics solutions as a managed service, allowing businesses to access advanced automation capabilities without the upfront investment.

With Amazon leading the charge and competitors following closely behind, the warehouse automation industry is poised for a period of rapid innovation and growth. As researchers and companies push the boundaries of what’s possible in robotics and automation, we can expect significant advancements in logistics and supply chain management.

VI. Challenges and Criticisms of Amazon’s Robotics Strategy

Amazon’s robotics strategy, which involves the deployment of increasing numbers of robots in its fulfillment centers, has faced numerous challenges and criticisms. Some of these concerns include:

Analysis of Concerns

Job Displacement:

Critics argue that Amazon’s robotic automation may lead to job losses for human workers, particularly those in low-skilled positions. This concern has gained significant attention given the ongoing debates about automation and employment.

Worker Safety:

Another concern relates to worker safety. Some workers have reported injuries from working alongside robots, which can be heavy and fast-moving. The potential for accidents is a valid worry, given the large scale of Amazon’s operations.

Privacy Issues:

Lastly, privacy concerns have arisen due to the extensive use of cameras and other sensors in Amazon’s fulfillment centers. These devices are necessary for robotics operations but raise questions about worker surveillance and data collection.

Discussion of Potential Solutions

To address these challenges, Amazon has taken several steps:

Training Workers for Higher-Skilled Tasks:

Amazon is investing in training its workforce for higher-skilled tasks, such as robot maintenance and programming. By upskilling its workers, it can reduce the likelihood of job displacement and create new opportunities.

Investing in Robot Safety:

To improve worker safety, Amazon is investing in robot safety technologies, such as sensors and collision avoidance systems. These features help prevent accidents by allowing robots to sense and react to their surroundings.

Transparency and Data Security:

Amazon is also addressing privacy concerns by providing transparency about its data collection and storage practices. It ensures that data is anonymized and used only for operational purposes.

By addressing these challenges, Amazon aims to mitigate potential issues while continuing to reap the benefits of its robotics strategy.

V Conclusion:

Amazon’s robotics initiatives have

warehouse automation

, setting new standards for efficiency, productivity, and accuracy. By

integrating robotic technology

into their operations, Amazon has been able to streamline processes, reduce labor costs, and enhance customer experience.

Moving forward, the future direction of

warehouse automation

looks promising with potential advancements and applications extending beyond traditional warehousing. One such area is the integration of

artificial intelligence (AI) and machine learning (ML)

algorithms, which can enable predictive maintenance, optimize inventory management, and improve order fulfillment accuracy.

Another promising application is the use of

autonomous mobile robots (AMRs)

for order picking and transportation within warehouses. These robots can significantly reduce travel time, freeing up human workers to focus on more complex tasks. Moreover, the integration of drones for in-warehouse inventory management and last-mile delivery is another potential area of growth.

In the grand scheme of things, Amazon’s role in

driving innovation in the industry

is unparalleled. As the world’s leading online retailer, Amazon sets the bar high for e-commerce logistics and supply chain management. By continuously investing in robotics, automation, AI, ML, and other advanced technologies, Amazon is shaping the future of e-commerce logistics. Their initiatives not only benefit their own operations but also inspire competition and innovation among other players in the industry.

In conclusion, Amazon’s investments in robotics and automation have revolutionized warehouse operations, and the future looks bright with potential advancements in AI, ML, AMRs, and drones. Amazon’s role as an industry leader will continue to shape the future of e-commerce logistics and set new standards for efficiency, productivity, and customer experience.